ArcelorMittal steel for Switzerland’s first decarbonised steel structure

Morand Constructions Métalliques is building Switzerland’s first decarbonised steel structure with ArcelorMittal’s XCarb® recycled and renewably produced steel beams in Rossens.

Reducing the carbon footprint of steel construction

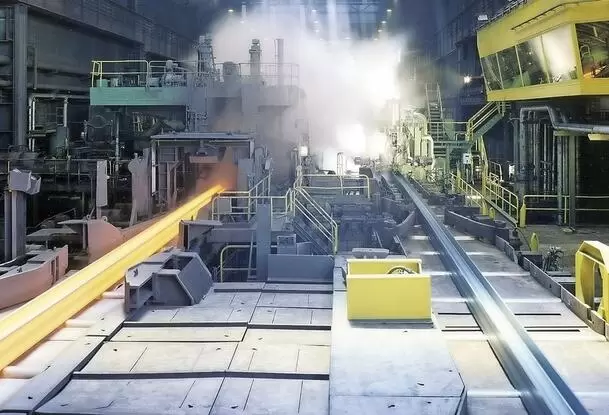

Approximately 60 tonnes of XCarb® recycled and renewably produced steel beams from ArcelorMittal’s mill in Luxembourg are being delivered to Switzerland where Morand Constructions Métalliques will erect the country’s first structure made with decarbonised steel - the future DIMAB car dealership in Rossens.

ArcelorMittal Steligence® CEO, Olivier Vassart, explains that this steel, which has been certified by the Institute Bauen und Umwelt and by a German life cycle specialist, combines two key characteristics: "It is composed entirely of recycled scrap metal, and this scrap metal is melted in an electric arc furnace powered by renewable electricity from either the wind or the sun.” The production of one tonne of primary steel generates around 2.3 tonnes of CO2, whereas recycled steel combined with the use of an electric arc furnace generates 0.6 tonnes of CO2 per tonne of steel. Through the use of renewable energy, emissions are reduced to 0.333 tones of CO2 per tonne of steel.

This 333 kg of CO2 is still reducible: "We are working on it,” explains Olivier Vassart. “These emissions are linked to the transport of recyclable scrap metal, the extraction and transport of the added minerals (manganese, silicon, copper), and the gas that is still essential to the process, particularly for heating the steel before rolling."

Demand is growing

"Few engineers and project owners are aware of this possibility, which makes it possible to greatly improve the carbon footprint of steel constructions," notes Jean-François Suchet, Director of Morand Constructions Métalliques. However, demand for this steel is growing in Europe says Olivier Vassart: "Our overall production in Luxembourg is around 2 million tonnes of steel per year. It is decarbonised at the customer's request. In one year, this corresponds to 100 000 tonnes.”

Text:

Constructalia

Images:

ArcelorMittal