Fig.5: Weight comparison UPE/UPN:

Fig.6: Comparison of section module Wy - UPE/UPN:

Fig.7: Comparison of section module Wz - UPE/UPN

Fig.8: Comparison of specific resistance UPE/UPN - strong axis

Fig.9: Comparison of specific resistance UPE/UPN - weak axis

UPE: A new range for lighter structures and easier assembly

With their U sections, smaller thicknesses, and wider parallel flanges, the products in the UPE range area are a good replacement for the UPN ranges. UPE is associated with lightness, strength, economy, and efficiency.

The UPE range is available in all the usual constructional steel grades and in heights from 80 to 400 mm. The heights of sections in the UPE range correspond to those in the IPE range. In comparison to UPN, this presents an advantage concerning the connections with IPE sections in structures where different types of sections are used.

This compatibility of the IPE and UPE section ranges does not apply with the UPN sections as five of the heights do not correspond with those of the IPE. (Table 1)

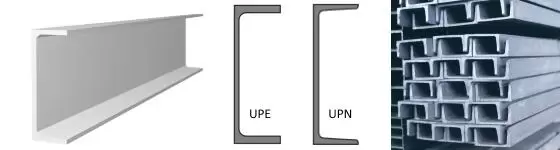

Fig.1: UPE and UPN sections

Easier and more profitable: save assembly time

The UPE range has parallel flanges, which simplify connections when compared to the tapered flanges of UPN sections.

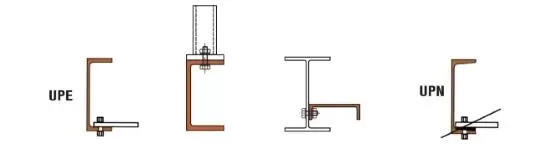

In order to compensate for the flange slope of the UPN sections, bolts, wedges, and bevels have to be used for the connections, making the assembly more difficult and slower. (Fig.2)

Fig.2: Connections of UPN sections with tapered flanges

The parallel flanges of the UPE sections allow for simpler connections, avoiding the use of tapered wedge and facilitating the execution of transversal connections. (Fig.3)

Fig.3: Connection of UPE sections with parallel flanges

Simple assemblies are also possible on the inside or the outside of the flanges thanks to the parallel flanges of UPE. (Fig.6)

Fig.4: Connection on the inside and outside of the flanges

Lighter and, therefore, more competitive

The lightening of structures can save up to 11% on the investment.

The UPE sections are lighter, giving a significant saving in weight per square metre in constructions (Fig.5) while improving profitability and reducing construction and maintenance costs.

Fig.5: Comparison of UPE/UPN weight

The web and flanges of the UPEs are thinner than those of the UPN range resulting in a weight reduction of around 11% when using UPE. (Table 2)

Stronger = higher performance: gain up to 42% in strength

The UPE section has a better relation load-bearing capacity/weight-per-metre than UPN sections. The increase in strength is from about 9% up to 34% depending on the application.

The UPE sections present advantages in the section modulus and the specific resistance per weight in comparison with the UPN range, both on the strong and the weak axis.

UPE sections have wider flanges than UPNs. Thanks to the greater rigidity in the weaker axis, up to 42% in strength can be gained when calculating the bending elements with respect to this axis.

Although UPE sections are lighter than UPNs, the modules of resistance with respect to the weak axis of the UPE profiles are 33% higher than the UPN (Fig.7). When compared the strong axis of UPE, the modules of resistance are comparable to those of the UPN (Fig.6).

The yields (specific resistance W/weight G) with respect to the weak axis of UPE profiles are up to 42% higher than those of UPN (Fig.9), and those in relation to the strong axis are up to 13% higher than with UPNs.

Fig.8: Comparison of specific resistance UPE/UPN - strong axis

Fig.9: Comparison of specific resistance UPE/UPN - weak axis

In summary, UPE sections offer significant gains in terms of weight reduction, competitiveness, and simplified connections compared to the UPN range.

As a final point, the most common applications of U sections in steel construction are beams (for flooring or roofing), columns (support), metalworking elements (stairs), connecting elements (lines), and facade elements (sunscreens).

Author: Fabián Mejia Pinto, ArcelorMittal Europe - Long Products

Related link(s)

MoreTable 1: Height of UPN, UPE, and IPE sections

Table 2: Comparison UPE/UPN: weight, section modulus, and specific resistance