ACB®

Cellular beams

Technical information

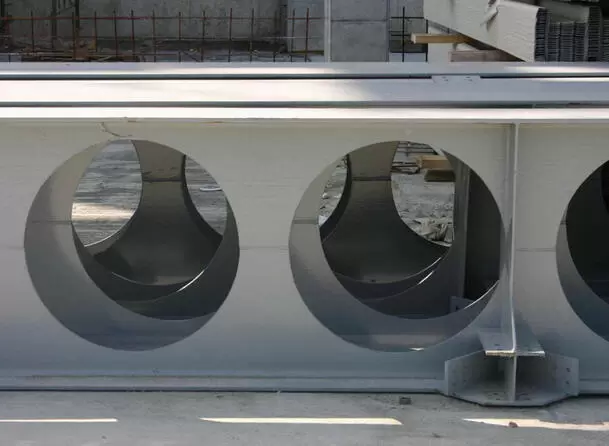

ACB® beams are fabricated based on the exclusive use of hot rolled sections.

A double cut-out is made in the web by flame cutting. The two obtained T-sections are shifted and rewelded leading to an increase in height.

The obtained structural product has an increased ratio of moment of inertia / weight. For a given section, the diameter and the spacing of openings are variable resulting in an extremely adjustable beam geometry and perfect suitability to project requirements.

Objective: Optimisation of the height/weight ratio

Applications: roofing, gangways/footbridges, wide-span purlins

Common steel grades: S235, S275, S355

Objective: Optimisation of the load/weight ratio

Applications: floors, car parks, offshore structures

Common steel grades: S355, S460, HISTAR® 460

Base profiles:

IPE300 – IPE750, HE240 – HE1000, HL920 – HL1100, HD260 – HD400, UB305 – UB1016, UC305 – UC356, W310 – W1100

Light, aesthetic & functional

The lightweight appearance of ACB® cellular beams combined with their high strength never ceases to inspire architects in new structural forms. The optimised height/weight or load/weight ratio provides effective answers to the demands of project owners.

This solution allows for large uninterrupted spaces with spans of up to 18 metres and technical installations like pipes and ducts that can pass through the beams' circular web openings.

Fire resistance in steel structures: theoretical fundamentals and real case scenario of the natural fire safety concept

In this technical article, Gian Carlo Giuliani, structural engineer at Redesco, presents the theoretical fundamentals of fire resistance calculations for structures through the presentation of a case study: the steel structure of a commercial centre in Cyprus.

1. Fire safety assessment of structures: general approach

A structure subjected to fire must be safe for the time necessary for the escape of the people and for the safe operation of the rescue and fire brigade; the verification is based on the fulfilment of the following conditions for the evacuation time and the safe operation of the fire brigade:

- R structural resistance

- E structure and pavement smoke tightness

- I isolation or limit of the temperature of the floor above the fire

These conditions are verified taking into account the temperature versus time evolution by means of:

- for the R condition: a step by step analysis of the temperature in the ambient and in the structural elements, followed by the verification of the load bearing capacity resulting from the reduction of the material mechanical parameters

- a verification of the existence of a structure capable of satisfying the E and I conditions

The assessing of the structure is related to the actual use of the building and to the relevant amount of possibly combustible materials; therefore, the calculations are based on the temperature development induced by a real fire in a closed space, which is bound by the floor, the ceiling, and the edge partitions and connected to the open air through the side openings.

The standard fires, recommended by codes for the structural design or by the national laws, show a continuous increase of temperature which, because of the correspondent reduction of the strength of the materials, limits the time of the load bearing capacity of the structure.

On the contrary, the real fires can evolve from the amount of possibly burning material and from the oxygen available in the space or drawn in through the side openings and therefore always have a decay phase.

2. Shopping centres & fire safety: special requirements

In many cases, recent shopping centres are based on large column grid lines and are developed over two or three stories; a steel-concrete composite structure is a very efficient solution for the floors.

Because of the appealing contrast between the elegant exhibited goods and the high technical aspect of the in sight structure, the application of any passive fire protection spoils the architectural results and only sprinkler systems are accepted.

Therefore, the 'naked' structure fire resistance has to be assessed for the real operating conditions.

In annex A of Eurocode 1, the temperature evolution developed by the natural fire is defined as depending on the fuel amount and on the ventilation conditions given by the compartment geometry, the boundary thermal characteristics, and the openings.

Other parameters, defined in annex E of Eurocode 1, are related to the danger of fire activation as per table E1 and to the function of active fire fighting measures, as per table E2.

3. A real case scenario

The fire resistance assessment is developed for the composite steel-concrete floor of a building which is composed of main beams continuous over 8 m spans and of secondary ones also continuous over 16 m spans.

The design value of the fire load qf,d is defined as: qf,d = qf,k m δq1 δq2 δn (MJ/m2).

Where m = 0.80 is the combustion factor of the material.

δq1 = is a factor taking into account the fire activation risk due to the size of the compartment

δq2 = is a factor taking into account the fire activation risk due to the type of occupancy

δn = Πδni = 0.237 is a factor taking into account the different active fire fighting measures (sprinkler, detection, automatic alarm transmission, fire fighters). These active measures are generally imposed for life safety reasons.

qf,k (MJ/m2) is the characteristic fire load density per unit floor area.

The temperature raising depends on the kind of the fire which can occur:

- a general fire which is controlled by the ventilation

- a local fire which is controlled by the fuel amount

Each one of the above said conditions yields a completely different result.

The temperature evaluation was performed for two basic fire conditions:

• local fire in a department store bounded by wood shelves; this condition yields a fire development governed by the fuel and is more stringent than the following one

• general fire in the total floor surface bounded by masonry walls with few openings; this condition occurs as a consequence of the local fire and yields a fire development governed by the ventilation

For the examined case history, according to the site and the building features, the following parameters were used for the calculations taken from tables E1 and E2 of EC1:

δq1 = 1,60 is a factor taking into account the fire activation risk due to the size of the compartment

δq2 = 1,00 is a factor taking into account the fire activation risk due to the type of occupancy

δn1 = 0,61 automatic water extinguishing system

δn2 = 0,87 independent water supplies

δn3 = 1,00 automatic fire detection & alarm – by heat

δn4 = 0,73 automatic fire detection & alarm – by smoke

δn5 = 0,87 automatic alarm transmission to fire brigade

δn6 = 1,00 on site fire brigade

δn7 = 0,78 off site fire brigade

δn8 = 0,90 safe access routes

δn9 = 1,00 fire fighting devices

δn10 =1,00 smoke exhaust system

Because of the above said parameters, the fire can be controlled by fuel or by ventilation; the growth rate of the fire was selected as fast (tlim=15 minutes) in all the calculations.

The strategy adopted for the fire resistance assessment was based on the calculation of the maximum amount of possibly burning material which can be stored in the compartment having the internal height h=4.50 m; the goods on show are mainly composed of cellulosic clothes and tissues having a specific calorific value Hu=20.00 MJ/kg (the same parameter for the wood is 17.5) and a combustion factor m=0.80.

Two different scenarios were used for the fires controlled by the fuel amount or by the ventilation; the growing rate of the fire was selected as fast with the corresponding limit time tlim=0.25 hours.

The relevant parameters are indicated in the following table:

(*) qtd (MJ/m2)=qfdAf/At

(**) tmax=max(0.0002qtd; tlim)

In general, the fire governed by the ventilation lasts for hours but with temperatures below the steel critical ones.

An interesting remark is given for the above said condition:

- the amount of air necessary for burning one kg of cellulosic material with the relevant calorific value of Hu=20MJ/kg is Aa=0,312Hu+0.65=6.89 kg/kg

- being ρ =1.225 kg/m3 the specific mass of the air, the specific air volume which is necessary for burning the material is Va=5.62 m3/kg

- given the compartment volume V=23040 m3, the total mass M of the material which can burn by using the inside air is therefore given by M=V/Va=4100 kg, which corresponds to an average distribution of M/AF=0.8 kg/m2 <f.

The evolution of the temperatures developed by the natural fire is defined by the following function as per annex A of Eurocode 1; a decay branch of the temperature curve is taken into account because the temperature increasing of the steel is shifted in time and the maximum value appears during the ambient cooling phase.

The gas temperature versus time is therefore given by the function:

with t expressed in hours.

4. Loading condition and material mechanical properties concurrent to the fire

- the fire was considered an exceptional loading condition

- the fire, originating in the floor, was considered a local hazard

- the material resistance safety factors were reduced accordingly to the temperature (Figure 6)

- the loading safety factors were reduced also gg =1.0, gq=1.0 and the design live load q was reduced by a participation factor ψq =0.7 related to the use of the area

Figure 6: Scheme of the moment redistribution for an edge bay of the continuous beam

5. Structural analysis procedure

A step by step versus time procedure for both cases was used for calculating the temperatures of the fire and of the materials for determining the correspondent resistance.

- set time to 0s

- increment time 5s

- calculate the temperature of the standard fire versus time

- calculate the correspondent temperature of the steel according to the mass / exposed surface ratio of the beams and of the material and fire parameters

- calculate the resistance of the steel and of the concrete correspondent to the temperature

- for the mid span and the support sections calculate the ultimate resistance according to the schemes below:

- perform an elastic-plastic structural analysis taking into account the action redistribution between the most exposed sections towards the ones subjected to a lower temperature according to the scheme of figure 6: at the ultimate state, the mid span moment capacity is given by Mus=M1R+M2R/2 and the maximum resisted load is qu=8Mus/L2

- verify the resistance to the vertical shear at supports and the studs subjected to the horizontal shear

- compare the structure resistance R with the action A of the supported load

- if R>A start a new iteration; if not, the time resistance is determined because, due to the exhaustion of its redistribution capability, a part of or the whole structure is transformed into a mechanism.

In the examined case history, because of the limited stiffness of the columns and of the sliding supports at the relevant bases, the axial forces introduced in the beams by the constraint of the thermal strains were not crucial for the ultimate bending resistance.

6. Calculation of the steel temperatures

The calculation of the temperatures takes into account the geometry of the structure:

- the bottom flange of a beam is directly hit by the fire

- the web and the upper flange are in shadow from the flame radiating effect and therefore are subjected to a lower temperature

- the top of the reinforced concrete slab and the relevant reinforcement are subjected to a much lower temperature

The following relations, taken from Eurocode 4, were used for the calculation of the temperature of the structural steel:

where :

kshadov - is a correction factor for the shadow effect

ca - is the specific heat of steel (J/kgK)

ρa - is the density of steel (kg/m3)

Ai - is the exposed surface area of the part 'i' of the steel cross-section per unit length (m2/m)

Ai/Vi - is the section factor (m-1) of the part 'i' of the steel cross-section

Θa,t - is the steel temperature at time t (°C) supposed to be uniform in each part of the steel cross-section

Δt - is the time interval (sec)

The shadow effect was determined from:

With e1, b1, ew, hw, e2, b2, and cross sectional dimensions.

Because of the different section sizes and of the continuity conditions (Figure 4), the verifications were effected for any single element of the structure; the results for the edge bay of a secondary beam over the 16 m span are illustrated in figures 7 and 8.

Commercial contacts

Contacts

-

ArcelorMittal Commercial Sections - Austria GmbH

Sales Austria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Netherlands B.V

Sales Belgium & The Netherlands

ArcelorMittal Commercial Sections -

ArcelorMittal Zenica

Sales Bosnia & Herzegovina

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Bulgaria

Sales Bulgaria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Czech

Sales Czech Republic

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Denmark ApS

Sales Denmark

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Finland OY

Sales Finland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections France S.A.S

Sales France

ArcelorMittal Commercial Sections -

ArcelorMittal Träger und Spundwand GmbH

Sales Germany & Switzerland

ArcelorMittal Commercial Sections -

Arcelor Mittal Commercial FCSE Greece Ltd.

Sales Greece & Cyprus

ArcelorMittal Commercial Sections -

Gudmundur Arason EHF

Sales Iceland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections Italia Srl

Sales Italy

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Norway A/S

Sales Norway

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Polska

Sales Poland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Romania S.R.L.

Sales Romania

ArcelorMittal Commercial Sections -

ArcelorMittal Comercial Perfiles España S.L

Sales Spain

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Sweden A.B.

Sales Sweden

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Çelik Deş Ticaret A.Ş.

Sales Turkey

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long UK Ltd

Sales UK

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Baltics

Sales Estonia, Latvia & Lithuania

ArcelorMittal Commercial Sections

Technical contact

Contacts

-

Steligence®

Technical Advisory

ArcelorMittal Commercial Sections