Wire ropes

Wires

Related news and technical articles

ArcelorMittal wire rope helps Val d'Isère prepare for the next ski season

7 September 2022After more than 20 years of service on the Glacier chairlift in Val d'Isère, France, the ArcelorMittal wire rope has been replaced and 100% recycled. The new wire rope, at 32 tonnes and 3.8 km long, was produced by ArcelorMittal WireSolutions’ Bourg-en-Bresse site. After its reopening, the Glacier chairlift will be able to transport 3000 people per hour at a speed of 5 m/s and at an altitude of over 2800 m.

Project newsTéléo Toulouse: ArcelorMittal ropes in France’s longest urban cable car

31 May 2022Three kilometres long. Three stations. 15 cabins. 8000 users expected per day. These are the key facts about the new urban cable car in Toulouse, France - the longest one in the country - that opened in May 2022. ArcelorMittal WireSolutions contributed to the project by supplying 55 tonnes of innovative Whisper® ropes.

Project newsAscending an iconic monument with ArcelorMittal ropes

12 April 2022With more than 6 million visitors each year*, the Eiffel Tower is one of the most visited monuments in the world. The east pillar visitor lift is now equipped with ArcelorMittal’s Corzal® coated 6-strand compacted ropes, enabling visitors from all around the world to ascend (and descend!) this iconic structure to enjoy the magic of Paris. The ropes were provided by WireSolutions’ Bourg-en-Bresse plant.

Project news

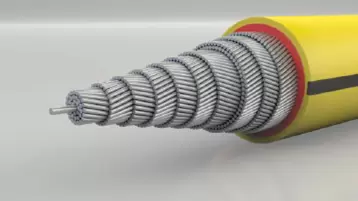

Ropes engineered with excellence

Wire ropes from ArcelorMittal are recognised worldwide for their strength, flexibility, and endurance. The high quality and corrosion resistance of the ropes make them a safe and long-term solution for the most demanding environments.

ArcelorMittal ROPES designs and manufactures ropes for the following applications:

- Ropeway ropes: steel ropes for urban and mountain transport of people and goods that can withstand extreme weather conditions and continuous use

- Mooring ropes: ArcelorMittal’s single and double-sheathed mooring ropes suit engineering and oil companies’ requirements for floating production installations for underwater use with lifespans of up to 35 years.

- Hoisting ropes: resistant and efficient ropes for lifting, lowering, and hoisting applications in the most demanding environments

- Mining ropes: technologically advanced wire ropes with long-term safety performance, engineered for the most aggressive mining environments.

Engineering excellence and innovation are at the core of ArcelorMittal ROPES. World-class technical expertise guarantees customer support at all project stages, and a fully integrated business model allows complete material traceability.

ArcelorMittal ROPES’ commitment to quality and the highest product and service performance standards is the result of our commitment to a process of continuous improvement.

Technical description

Ropeway ropes: 6-strand ropes, Whisper®, full lock coil, full lock coil with fibre optics, and HP8P

Mooring ropes: single sheathed and double sheathed ropes with diameters from 50 to 171 mm, available in high strength and with very good torque balance

Hoisting ropes: HDHP6, HP8P, Complast 9, Integral 8, NRHD 24 and 24C, Notor HP, and Notor HP Plast

Mining ropes: Klondike®, Notorplast®, NRHD 24 /24 CS, FLC Z-Lock, FLC Z-Lock (Track Rope), HLC X-Lock, and NCR6