Composite deck

OBJECTIVE/SCOPE

To describe the design of one-way spanning composite deck formed using profiled steel sheeting and a concrete topping, including consideration of ultimate and serviceability limit state design according to Eurocode 4: Part 1-1 [1] for building structures.

RELATED WORKED EXAMPLES

Worked example 10.4: Design of a composite deck

SUMMARY

Descriptions of composite slabs, typical profiled sheeting, and means of ensuring composite behaviour are given. Design criteria are identified in terms of loads, design resistance, and serviceability limits. Analysis of continuous slabs is based on elastic or plastic theories. The resistances of critical cross-sections are calculated considering all possible modes of failure. The design for the ultimate limit state design consists of checking that slab resistance is sufficient to withstand maximum predicted forces. Design for the serviceability limit state is performed to limit concrete cracking and slab deflections, taking into account creep and shrinkage of the concrete. The above methods are illustrated by Worked example 10.4.

1. INTRODUCTION

1.1 Definition

A composite deck consists of a cold-formed profiled steel sheet covered with a concrete slab containing reinforcement (see Figure 1). Such slabs are generally used in frame structures, with steel floor beams, as discussed previously in Composite construction - general. They can also be used in combination with other materials.

In this type of construction, the profiled sheet has several functions:

- it provides a working platform for construction

- it acts as formwork for the concrete slab

- it constitutes bottom reinforcement for the slab

The present lecture is mainly concerned with composite slabs when the steel-concrete bond has been formed, i.e. after hardening of the concrete. Design for the construction stage, when the profiled steel sheet supports the weight of wet concrete, is only considered briefly.

1.2 Types of profiled sheet

There are many types of profiled sheet used for the construction of composite slabs (see Figure 2). These types vary in form, rib depth, rib spacing, sheet size, style of lateral over-lapping; in the methods of stiffening the flat elements of the profile; and in the methods of mechanical connection which ensure bond between the steel sheet and concrete slab.

The thickness of the sheets can vary from 0.75 mm to 1.5 mm, but in normal practice it lies between 0.75 and 1.0 mm.

The height of the profiled sheets can vary from 40 mm to 220 mm.

Whatever the particular requirements for a steel framed building, it is probable that they can be met by using a profiled sheet from this range, as the typical criteria for sound insulation, fire protection, maximum span, and maximum load can easily be met.

1.3 Steel-concrete connection

The bond between the concrete slab and the profiled sheet must be capable of transmitting longitudinal shear at the steel-concrete interface.

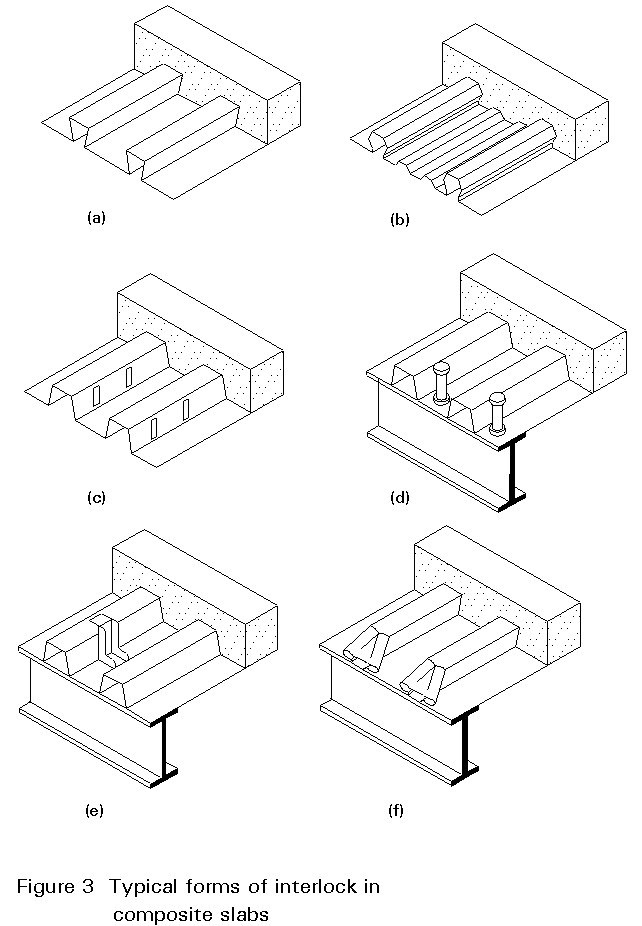

This connection can be made in one or more of the following ways, as shown in Figure 3 (which has been taken from Fig. 9.1 of Eurocode 4 [1]):

- by the re-entrant shape of the ribs creating bond by friction (see Figure 3a, b)

- by embossments on the flanges or ribs of the sheet (see Figure 3c)

- by anchorages situated at the ends of the slab, consisting of stud connectors welded through the sheet (see Figure 3d), shot-fired shear connectors (see Figure 3e), or by deformation of the ribs (see Figure 3f)

Read more

Prerequisites

Thin-walled members and sheeting

Read LectureComposite construction - general

Read LectureComposite beams - Shear connection part 1

Read Lecture