Prerequisites

Cross-section classification

Read LectureRelated lectures

Composite construction - general

OBJECTIVE/SCOPE

To introduce steel-concrete composite members and construction. To explain the composite action of the two different materials, and to show how the structural members are used, particularly in building construction.

SUMMARY

The two complementary materials, structural steel and reinforced concrete, are introduced, and it is shown how composite action is achieved in the case of composite slabs, beams, and columns. The use of composite construction for buildings and bridges is outlined and illustrated by several typical examples. Its main advantages are also illustrated by comparison with structures of steel and concrete used independently. Attention is drawn to the effect of this form of construction on other more general problems such as: fire resistance rating, speed of construction, flexibility, and final fitting out.

1. INTRODUCTION

The most important and most frequently encountered combination of construction materials is that of steel and concrete, with applications in multi-storey commercial buildings and factories, car parks, as well as bridges. These materials can be used in mixed structural systems, for example concrete cores encircled by steel tubes, as well as in composite structures where members consisting of steel and concrete act together compositely.

These essentially different materials are completely compatible and complementary to each other. They have almost the same thermal expansion, and they have an ideal combination of strengths with the concrete efficient in compression and the steel in tension. Concrete could also give corrosion protection and thermal insulation to the steel at elevated temperatures and, additionally, can restrain slender steel sections from local or lateral-torsional buckling.

In multi-storey buildings, structural steelwork is typically used together with concrete - for example, steel beams with concrete floor slabs. The same applies to road and railway bridges, where concrete decks are normally preferred. The extent to which the components or parts of a building structure should embody all steel construction, be constructed entirely in reinforced concrete, or be of composite construction depends on the circumstances. It is a fact, however, that engineers are increasingly designing composite and mixed building systems of structural steel and reinforced concrete to produce more efficient structures when compared to designs using either material alone. The first two photos give an impression of how and to what extent composite construction is used for multi-storey buildings: Picture 1 shows a construction site for a commercial building in London, UK. Picture 2 shows a factory building for the car industry in Germany.

Picture 1: Typical composite multi-storey steel-framed building during construction - a commercial building in London.

Picture 2: Typical composite multi-storey steel-framed building during execution - a factory building for the car industry in Germany.

It should be added that the combination of concrete cores, steel frame, and composite floor construction has become the standard construction method for multi-storey commercial buildings in several countries. Much progress has been made, for example in Japan, where the structural steel/reinforced concrete frame is the standard system for tall buildings. The main reason for this preference is that the sections and members, shown in Picture 3, are best suited to resist repeated earthquake loadings, which require a high amount of resistance and ductility.

Picture 3: The combination of concrete cores, steel frame, and composite floor construction has become the standard method for multi-storey construction in several countries.

Building with steel and composite elements experienced a renaissance during the 1980s, resulting in a profusion of new construction concepts and structural details.

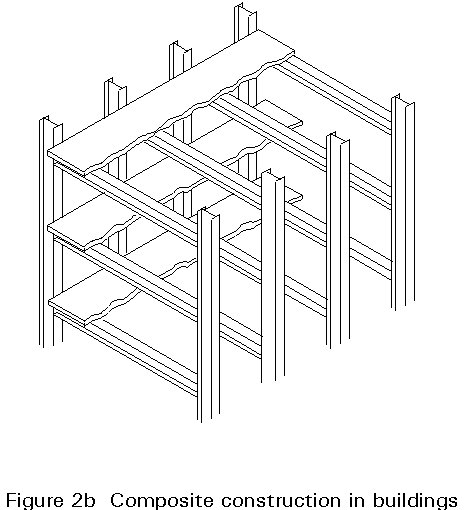

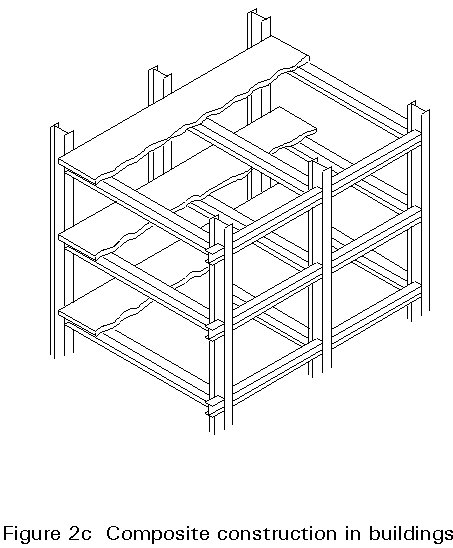

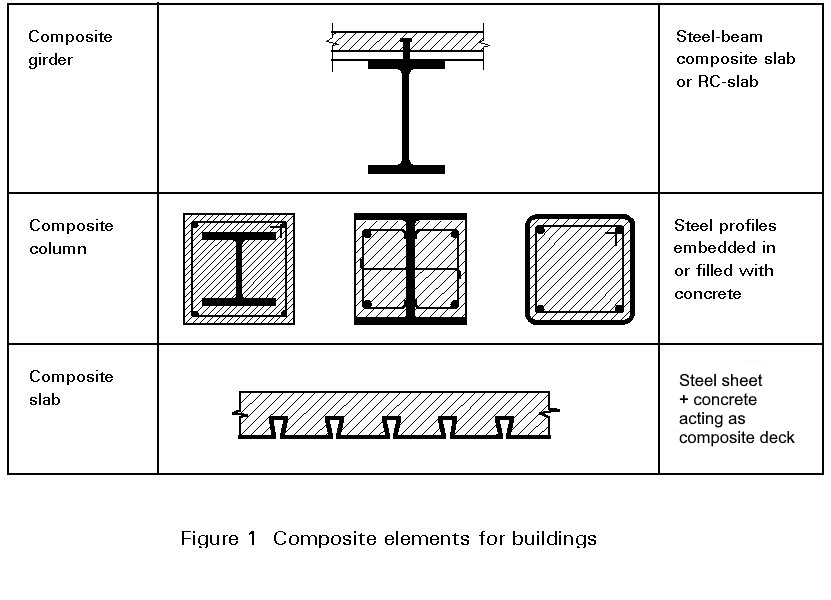

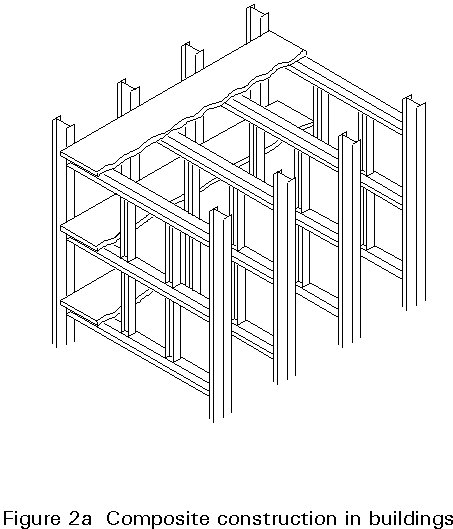

Single composite elements, such as isolated beams, columns, and slabs (see Figure 1), are of high quality and resistance, but they can also be costly. This is the case particularly for buildings with small column spacings, floor beam spans well below 9 m, and low loadings. On the other hand, composite floor construction is highly competitive if spans are increased to 12, 15, or even 20 m. There is a demand for larger column-free spans in buildings to facilitate open planning or greater flexibility in office layout, as shown in Figure 2.

A further important consideration is that the use of rolled steel sections, profiled metal decking, and/or prefabricated composite members speeds up execution. For maximum efficiency and economy, the joints should be cheap to fabricate and straightforward to erect on site.

Many experts feel that the further development of steel framed buildings depends largely on the use of composite construction.

Figure 2 shows three examples of the use of composite floor construction comprising steel beams and concrete slabs in buildings: Figure 2a shows a typical office building with offices on both sides of the corridor, the walls of which are defined by the positions of the internal columns; Figure 2b shows a large span, column-free structure, which allows a high amount of flexibility; and the structure in Figure 2c has a reduced number of columns with main and secondary beams.