HISTAR®

Structural steel grades

Advantages of HISTAR® by application

Solutions by

PerformanceTechnical information

HISTAR® steels are delivered in a thermomechanically rolled condition in accordance with the European Technical Approval ETA-10/0156. They comply with the requirements of the European standard EN 10025-4: 2019 for weldable fine grain structural steels and other national standards like ASTM A 913-11 and JIS G 3106:2008.

HISTAR® grades are compatible with the requirements of the Eurocodes for the design of steel structures and composite steel-concrete structures.

The steels are typically delivered with an Si content ranging between 0,14% and 0,25% and are as such capable of forming a zinc layer during hot-dip galvanisation. As the phosphorus content of these steels is usually lower than 0,035%, it does not have any influence on the final thickness of the coating in the considered Si range.

HISTAR® steels are produced in the modern EAF (Electric Arc Furnace) route, using 100% scrap as a raw material (upcycling). EAF steel production technology allows for significant reductions of noise, particle, and CO2-emissions and saves water and primary energy in the production process.

Solutions by

ConstructionResistant, economical, & sustainable

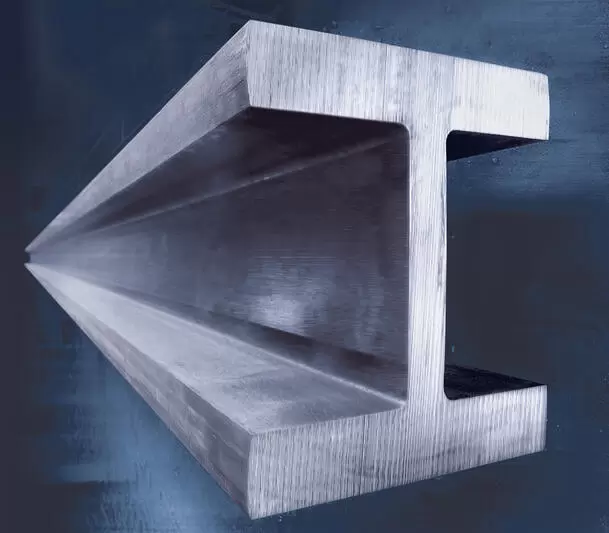

HISTAR® steels are innovative structural steel grades with a low alloy content available in yield strengths of 355 MPa and 460 MPa. HISTAR® grades combine high strength with excellent toughness at low temperatures and outstanding weldability - these material properties were considered incompatible until now.

The application of the innovative in-line heat treatment QST (Quenching and Self-Tempering) allows all HISTAR® grades, unlike most standard grades, to offer improved guaranteed values for yield strength over the whole product range.

- Considerable weight reduction and cost savings of steel structures

- Time savings in fabrication process: e.g. generally no preheating required for welding thanks to HISTAR®'s low carbon equivalent values

HISTAR® high strength steels are the ideal solution for structural applications where strong axial behaviour is key. In the shape of hot rolled Super Jumbo profiles, HISTAR® steels lead to automatic cost and material saving compared to conventional steel grades in the following applications:

In gravity columns (steel and composite columns with hot rolled profiles for higher resistance under axial compression, cruciform sections, and tailor-made solutions), the use of HISTAR® 460 compared to S355 brings an immediate 30% improvement of the axial stress resistance in relation to cost, weight savings, and gains in net carpet area. In long span trusses, the use of HISTAR® steels reduces the size and weight of its members, allowing for more economical and lighter designs. The same applies to belt trusses and outriggers, which improve stiffness and strength and add torsional resistance in high rise buildings. In foundation solutions, considerable weight savings are automatically ensured when using HISTAR® for HZ®-M King piles in axial compression.

Useful information

MoreRelated news and technical articles

Connections made of jumbo and super jumbo steel shapes: a practical guide

28 May 2024ArcelorMittal, a leading global producer of steel shapes used in construction, created this handbook that brings together advice and information on connecting jumbo and super jumbo steel shapes in building structures not subject to seismic loading. It is aimed at designers, offering them insights into international best practices and additional resources beyond those of typical European and American building standards.The handbook draws heavily from the ECCS (European Convention for Constructional Steelwork) book ‘Joints in steel and composite structures,’ which focusses on structural connections and covers topics such as how to design, fabricate, and assemble these connections.

Technical articleKraków railway bridge: a titanic and Luxembourgish construction

8 January 2024ArcelorMittal contributed to one of the largest Polish railway projects of the decade: the reconstruction of the E-30 railway corridor in Kraków and the modernisation of several stations connecting two districts of Kraków.

Project newsSuccesses for sustainable construction at BAU

27 April 2023ArcelorMittal took part in BAU, a major event for the construction and building industry, in Munich from 17-22 April, showcasing its latest high-performance steel products, XCarb® range of sustainable steels, and cooperations dedicated to construction.

Event news

Connections made of jumbo and super jumbo steel shapes: a practical guide

Published: 28 May 2024

ArcelorMittal, a leading global producer of steel shapes used in construction, created this handbook that brings together advice and information on connecting jumbo and super jumbo steel shapes in building structures not subject to seismic loading. It is aimed at designers, offering them insights into international best practices and additional resources beyond those of typical European and American building standards.

The handbook draws heavily from the ECCS (European Convention for Constructional Steelwork) book ‘Joints in steel and composite structures,’ which focusses on structural connections and covers topics such as how to design, fabricate, and assemble these connections.

Optimising design and cost

This handbook provides guidelines for effectively designing, building, and assembling projects that involve large and exceptionally thick steel sections, known as ‘jumbo shapes’ and ‘super jumbo shapes.’ These shapes have flange thicknesses equal to or greater than 50 mm as defined by standards such as EN 10365 and AISC 360 (2016). Due to their size and thickness, special attention is needed when connecting these steel shapes to ensure safety and structural integrity.

Steel is an anisotropic material, which means it has different properties depending on the direction in which it rolled. For hot rolled structural shapes, the best properties are found in the direction of rolling, and it is crucial to consider properties across the thickness of the material (through-thickness properties). This is especially important for welded connections, where improper planning can lead to weld strains surpassing the material's strength. Therefore, careful planning and coordination among project stakeholders – including design engineers, architects, fabrication shops, assemblers/erectors, quality control offices, and suppliers – are essential to create efficient connections.

Throughout the stages of design, detailing, fabrication, and erection of a steel structure, there is room for optimising cost-effectiveness. Designers and detailers can work together to find the most efficient solutions, taking into consideration the capabilities of the fabricator. Prefabricating components in the workshop not only streamlines transport and installation on site but also influences the design of connection types, which can positively impact the project's costs. The more prefabrication done in the workshop, the higher the quality and cost-efficiency of the steel structures.

Design requirements and material specifications

Connections must be strong enough to support applied forces without compromising the structure's stability. They should be designed to:

- be robust enough to guarantee structural integrity

- minimise any additional effects on the structure

- allow for sufficient rotation

- be able to sustain cyclic loads where needed

Welded connections of jumbo and super jumbo profiles, especially those made from high strength steel, require specific expertise. This involves understanding the welding process and choosing appropriate steel materials, including filler metals. Welded connections, especially those experiencing tension and bending forces, need careful consideration.

We recommend that designers consult ArcelorMittal's technical advisory department (steligence.engineering@arcelormittal.com) for guidance, especially when dealing with flange thicknesses exceeding 50 mm for ML sub-grade and 80 mm for M sub-grade steel.

Contents of this handbook

Chapter 1 discusses how choosing the right type of steel is crucial for ensuring the longevity of a structure. It provides guidance from ArcelorMittal on how to select the appropriate steel grade throughout the design process, from the initial stages to when the steel is used as a structural element. The chapter covers concepts like ductility, through-thickness properties, and material characteristics in detail. It also introduces the concept of fracture toughness and explains its importance. The chapter further delves into the methodology for selecting materials based on fracture toughness according to a specific standard, EN 1993-110:2005, particularly for components subjected to quasi-static compression loading.

In Chapter 2, welded connections are detailed, starting from design code principles to the metallurgical perspective. It emphasises the importance of preparing jumbo beams before welding to ensure quality and minimise fabrication costs. The chapter discusses how steel's ductile nature doesn't necessarily translate into a ductile structure and explains the strategic placement of weld access holes. Additionally, it covers lamellar tearing, a type of cracking related to welding in the base material, and provides guidance on avoiding and detecting it. Various welding parameters such as welding processes, electrodes, heat input, and post-weld heat treatment are highlighted as crucial for executing proper welds and ensuring reliable connections.

Chapter 3 classifies connections based on their structural role and the external loads they endure. It includes categories like connections subjected to tension and compression loads, beam and column splices, trusses, and beam-column connections. The chapter also showcases examples of actual structures utilising connections of jumbo shapes.

Chapter 4 addresses the key factors influencing the connection of jumbo profiles, including architectural considerations, specifying the correct steel shape and grade, manufacturing processes, safety measures, and transportation requirements.

The handbook is supplemented with several Annexes: Annex A presents an example of butt welding with H5 of HD 400 x 1299 (tf = 140mm) in HISTAR® 460, Annexes B and C detail proper steel specification for a column under axial and eccentric compression respectively to avoid brittle fracture, and Annex D provides a design example for a column splice of the bearing type with no net tension (HD 400 x 744 and HD 400 x 990).

Text:

Constructalia

ArcelorMittal Global R&D

Images:

ArcelorMittal

Related link(s)

Connections made of jumbo and super jumbo steel shapes: a practical guide

Weld preparation of Jumbo Beams

Super Jumbos: Extra Heavy Section Sizes

Jumbo solutions for complex challenges: W14x930 and W14x1000

Kraków railway bridge: a titanic and Luxembourgish construction

ArcelorMittal contributed to one of the largest Polish railway projects of the decade: the reconstruction of the E-30 railway corridor in Kraków and the modernisation of several stations connecting two districts of Kraków.

The project

Started in 2017, work on the E-30 railway corridor includes the total reconstruction of a railway bridge over Poland's largest river - the Vistula - in the centre of Kraków.

Initially, a simple partial renovation was planned with the addition of two additional bridges on either side of the existing deck, but after technical and financial analyses, it was decided to construct a complete set of three new bridges. In 2020, the City of Kraków and the investor, PKP PLK S.A., agreed to extend the scope of works by installing a cycle and pedestrian path on the outer deck, leading to a change in the design and an increase in the width of the bridge.

HISTAR® for extraordinary constructions

ArcelorMittal and its beam finishing centre (BFC-LPL) based in Niederkorn, Luxembourg supplied 1300 tonnes of HISTAR® 460 and was commissioned to carry out the cutting, bending, and chamfering of the beams for the preparation of the welds on the bridge site. With a total length of 229 metres, the largest reinforced concrete slab covers 1200 m3, and its pouring took twenty hours continuously. A unique feature of the solution included the use of HD 400 sections (in various sizes) in HISTAR® 460 for the arch elements on which the entire bridge is suspended. The use of heavy-duty HD profiles in this unique project significantly reduced the volume of material required and accelerated the on-site assembly process.

Today, this bridge is the longest and thinnest railway bridge of its kind ever built in Europe. After the first side of the bridge was put into service in May 2020, the second double-track bridge (the most central) opened in June 2022. It was in May 2023 that the third bridge was opened for rail traffic.

Text:

ArcelorMittal Luxembourg

Constructalia

Images:

© ArcelorMittal Europe

Related link(s)

Successes for sustainable construction at BAU

ArcelorMittal took part in BAU, a major event for the construction and building industry, in Munich from 17-22 April, showcasing its latest high-performance steel products, XCarb® range of sustainable steels, and cooperations dedicated to construction.

Cooperations featuring XCarb® recycled and renewably produced steel

Two exciting new cooperations were announced during the event:

- ArcelorMittal has joined forces with BP2, a manufacturer of complete solutions for residential construction, to supply low carbon emissions steel for BP2’s latest product, the SOLROOF integrated photovoltaic roof.

- The VELUX Group has kickstarted cooperation with ArcelorMittal as part of its efforts to halve value chain emissions by 2030. The companies will now work together to lower the carbon footprint of the steels used in VELUX roof windows, aiming to reduce embedded CO2 by up to 70% (depending on the type of steel product used) compared with conventionally produced steel.

High-performance steel products

Flagship ArcelorMittal products presented at the event included:

- Granite® organic coated steels for building envelopes: available in more than 120 colours and textures and guaranteed for up to 40 years with Granite® HDXtreme

- Magnelis® metallic coated steel for facade substructures, solar mounting structures, cable trays, composite floors, and many more applications: resists corrosion three times better than regular galvanised steel

- Ondatherm Solar®: special roof panels for photovoltaic systems

- Cofraplus® 80 composite floor profiles: approved by building authorities as prefabricated steel floors and with a significantly lower carbon footprint compared to prefabricated concrete slabs

- high strength HISTAR® steels: providing cost and material savings

- weather-resistant Arcorox® steel grade: with natural corrosion protection and a long service life

Text:

Constructalia

ArcelorMittal Europe

Images:

©ArcelorMittal Europe

©VELUX Group and ArcelorMittal

©BP2

©BAU

Related link(s)

Commercial contacts

Contacts

-

ArcelorMittal Commercial Sections - Austria GmbH

Sales Austria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Netherlands B.V

Sales Belgium & The Netherlands

ArcelorMittal Commercial Sections -

ArcelorMittal Zenica

Sales Bosnia & Herzegovina

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Bulgaria

Sales Bulgaria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Czech

Sales Czech Republic

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Denmark ApS

Sales Denmark

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Finland OY

Sales Finland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections France S.A.S

Sales France

ArcelorMittal Commercial Sections -

ArcelorMittal Träger und Spundwand GmbH

Sales Germany & Switzerland

ArcelorMittal Commercial Sections -

Arcelor Mittal Commercial FCSE Greece Ltd.

Sales Greece & Cyprus

ArcelorMittal Commercial Sections -

Gudmundur Arason EHF

Sales Iceland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections Italia Srl

Sales Italy

ArcelorMittal Commercial Sections -

Steligence Fabrication Center - ArcelorMittal Commercial Sections SA.

Beam Finishing

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Norway A/S

Sales Norway

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Polska

Sales Poland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Romania S.R.L.

Sales Romania

ArcelorMittal Commercial Sections -

ArcelorMittal Comercial Perfiles España S.L

Sales Spain

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Sweden A.B.

Sales Sweden

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Çelik Deş Ticaret A.Ş.

Sales Turkey

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long UK Ltd

Sales UK

ArcelorMittal Commercial Sections -

ArcelorMittal International Azerbaijan

Sales Azerbaijan

ArcelorMittal International -

ArcelorMittal International Africa

Sales Africa

ArcelorMittal International -

ArcelorMittal International Brazil

Sales Brazil

ArcelorMittal International -

ArcelorMittal International Chile

Sales Chile

ArcelorMittal International -

ArcelorMittal International Beijing

Sales China

ArcelorMittal International -

ArcelorMittal International Shanghai

Sales China

ArcelorMittal International -

ArcelorMittal International Urumqui

Sales China

ArcelorMittal International -

ArcelorMittal International Colombia

Sales Colombia

ArcelorMittal International -

ArcelorMittal International Ecuador

Sales Ecuador

ArcelorMittal International -

ArcelorMittal International Egypt

Sales Egypt

ArcelorMittal International -

ArcelorMittal International Mumbai

Sales India

ArcelorMittal International -

ArcelorMittal International Korea

Sales Korea

ArcelorMittal International -

ArcelorMittal International Mexico

Sales Mexico

ArcelorMittal International -

ArcelorMital Projects Nigeria

Sales Nigeria

ArcelorMittal International -

ArcelorMittal International Peru

Sales Peru

ArcelorMittal International -

ArcelorMittal International Moscow

Sales Russia

ArcelorMittal International -

ArcelorMittal International Senegal

Sales Senegal

ArcelorMittal International -

ArcelorMittal International Singapore

Sales Singapore

ArcelorMittal International -

ArcelorMittal International South Africa

Sales South Africa

ArcelorMittal International -

ArcelorMittal International Taiwan

Sales Taiwan

ArcelorMittal International -

ArcelorMittal International Celik Dis Ticaret A.S.

Sales Turkey

ArcelorMittal International -

ArcelorMittal International FZE

Sales United Arab Emirates

ArcelorMittal International -

ArcelorMittal International North America

Robert Caroti - Sales USA

ArcelorMittal International -

ArcelorMittal International Ukraine

Sales Ukraine

ArcelorMittal International -

ArcelorMittal International Venezuela

Sales Venezuela

ArcelorMittal International -

ArcelorMittal International Vietnam

Sales Vietnam

ArcelorMittal International -

ArcelorMittal International Luxembourg

Sales International

ArcelorMittal International -

ArcelorMittal International North America

Dhiren Patel - Sales Canada

ArcelorMittal International

Technical contacts

Contacts

-

Steligence®

Technical Advisory

ArcelorMittal Commercial Sections -

ArcelorMittal International North America

Joseph Dardis - Technical assistance

ArcelorMittal International