HISTAR®

Structural steel grades

Advantages of HISTAR® by application

Solutions by

PerformanceTechnical information

HISTAR® steels are delivered in a thermomechanically rolled condition in accordance with the European Technical Approval ETA-10/0156. They comply with the requirements of the European standard EN 10025-4: 2019 for weldable fine grain structural steels and other national standards like ASTM A 913-11 and JIS G 3106:2008.

HISTAR® grades are compatible with the requirements of the Eurocodes for the design of steel structures and composite steel-concrete structures.

The steels are typically delivered with an Si content ranging between 0,14% and 0,25% and are as such capable of forming a zinc layer during hot-dip galvanisation. As the phosphorus content of these steels is usually lower than 0,035%, it does not have any influence on the final thickness of the coating in the considered Si range.

HISTAR® steels are produced in the modern EAF (Electric Arc Furnace) route, using 100% scrap as a raw material (upcycling). EAF steel production technology allows for significant reductions of noise, particle, and CO2-emissions and saves water and primary energy in the production process.

Solutions by

ConstructionResistant, economical, & sustainable

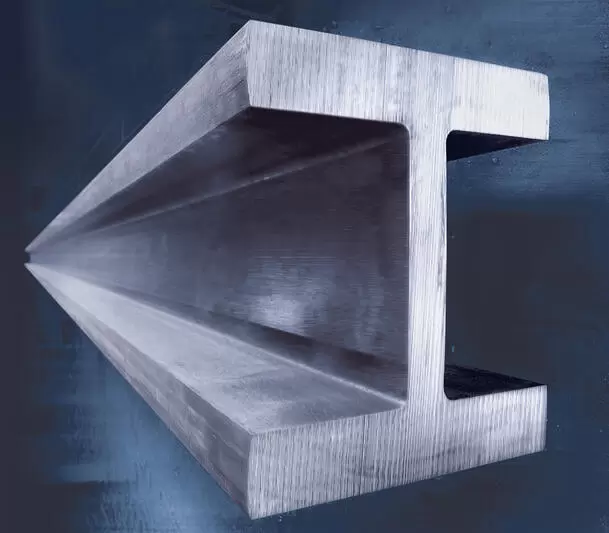

HISTAR® steels are innovative structural steel grades with a low alloy content available in yield strengths of 355 MPa and 460 MPa. HISTAR® grades combine high strength with excellent toughness at low temperatures and outstanding weldability - these material properties were considered incompatible until now.

The application of the innovative in-line heat treatment QST (Quenching and Self-Tempering) allows all HISTAR® grades, unlike most standard grades, to offer improved guaranteed values for yield strength over the whole product range.

- Considerable weight reduction and cost savings of steel structures

- Time savings in fabrication process: e.g. generally no preheating required for welding thanks to HISTAR®'s low carbon equivalent values

HISTAR® high strength steels are the ideal solution for structural applications where strong axial behaviour is key. In the shape of hot rolled Super Jumbo profiles, HISTAR® steels lead to automatic cost and material saving compared to conventional steel grades in the following applications:

In gravity columns (steel and composite columns with hot rolled profiles for higher resistance under axial compression, cruciform sections, and tailor-made solutions), the use of HISTAR® 460 compared to S355 brings an immediate 30% improvement of the axial stress resistance in relation to cost, weight savings, and gains in net carpet area. In long span trusses, the use of HISTAR® steels reduces the size and weight of its members, allowing for more economical and lighter designs. The same applies to belt trusses and outriggers, which improve stiffness and strength and add torsional resistance in high rise buildings. In foundation solutions, considerable weight savings are automatically ensured when using HISTAR® for HZ®-M King piles in axial compression.

Useful information

MoreRelated news and technical articles

Kraków railway bridge: a titanic and Luxembourgish construction

8 January 2024ArcelorMittal contributed to one of the largest Polish railway projects of the decade: the reconstruction of the E-30 railway corridor in Kraków and the modernisation of several stations connecting two districts of Kraków.

Project newsSuccesses for sustainable construction at BAU

27 April 2023ArcelorMittal took part in BAU, a major event for the construction and building industry, in Munich from 17-22 April, showcasing its latest high-performance steel products, XCarb® range of sustainable steels, and cooperations dedicated to construction.

Event news6000 tonnes of XCarb® recycled and renewably produced available for South East Asian market

6 October 2022XCarb® Recycled and renewably produced is now in stock in Singapore and available for the South East Asian market. Continental Steel, a major stockist in Asia, has recently purchased 6000 tonnes of XCarb® recycled and renewably produced sections. Through combined efforts between ArcelorMittal Europe – Long Products and the ArcelorMittal International Singapore office, Continental Steel are convinced they will gain a competitive advantage by being among the first distributors in Asia to promote and sell low CO2 emissions steel.

Product news

Kraków railway bridge: a titanic and Luxembourgish construction

ArcelorMittal contributed to one of the largest Polish railway projects of the decade: the reconstruction of the E-30 railway corridor in Kraków and the modernisation of several stations connecting two districts of Kraków.

The project

Started in 2017, work on the E-30 railway corridor includes the total reconstruction of a railway bridge over Poland's largest river - the Vistula - in the centre of Kraków.

Initially, a simple partial renovation was planned with the addition of two additional bridges on either side of the existing deck, but after technical and financial analyses, it was decided to construct a complete set of three new bridges. In 2020, the City of Kraków and the investor, PKP PLK S.A., agreed to extend the scope of works by installing a cycle and pedestrian path on the outer deck, leading to a change in the design and an increase in the width of the bridge.

HISTAR® for extraordinary constructions

ArcelorMittal and its beam finishing centre (BFC-LPL) based in Niederkorn, Luxembourg supplied 1300 tonnes of HISTAR® 460 and was commissioned to carry out the cutting, bending, and chamfering of the beams for the preparation of the welds on the bridge site. With a total length of 229 metres, the largest reinforced concrete slab covers 1200 m3, and its pouring took twenty hours continuously. A unique feature of the solution included the use of HD 400 sections (in various sizes) in HISTAR® 460 for the arch elements on which the entire bridge is suspended. The use of heavy-duty HD profiles in this unique project significantly reduced the volume of material required and accelerated the on-site assembly process.

Today, this bridge is the longest and thinnest railway bridge of its kind ever built in Europe. After the first side of the bridge was put into service in May 2020, the second double-track bridge (the most central) opened in June 2022. It was in May 2023 that the third bridge was opened for rail traffic.

Text:

ArcelorMittal Luxembourg

Constructalia

Images:

© ArcelorMittal Europe

Related link(s)

Successes for sustainable construction at BAU

ArcelorMittal took part in BAU, a major event for the construction and building industry, in Munich from 17-22 April, showcasing its latest high-performance steel products, XCarb® range of sustainable steels, and cooperations dedicated to construction.

Cooperations featuring XCarb® recycled and renewably produced steel

Two exciting new cooperations were announced during the event:

- ArcelorMittal has joined forces with BP2, a manufacturer of complete solutions for residential construction, to supply low carbon emissions steel for BP2’s latest product, the SOLROOF integrated photovoltaic roof.

- The VELUX Group has kickstarted cooperation with ArcelorMittal as part of its efforts to halve value chain emissions by 2030. The companies will now work together to lower the carbon footprint of the steels used in VELUX roof windows, aiming to reduce embedded CO2 by up to 70% (depending on the type of steel product used) compared with conventionally produced steel.

High-performance steel products

Flagship ArcelorMittal products presented at the event included:

- Granite® organic coated steels for building envelopes: available in more than 120 colours and textures and guaranteed for up to 40 years with Granite® HDXtreme

- Magnelis® metallic coated steel for facade substructures, solar mounting structures, cable trays, composite floors, and many more applications: resists corrosion three times better than regular galvanised steel

- Ondatherm Solar®: special roof panels for photovoltaic systems

- Cofraplus® 80 composite floor profiles: approved by building authorities as prefabricated steel floors and with a significantly lower carbon footprint compared to prefabricated concrete slabs

- high strength HISTAR® steels: providing cost and material savings

- weather-resistant Arcorox® steel grade: with natural corrosion protection and a long service life

Text:

Constructalia

ArcelorMittal Europe

Images:

©ArcelorMittal Europe

©VELUX Group and ArcelorMittal

©BP2

©BAU

Related link(s)

6000 tonnes of XCarb® recycled and renewably produced available for South East Asian market

XCarb® Recycled and renewably produced is now in stock in Singapore and available for the South East Asian market. Continental Steel, a major stockist in Asia, has recently purchased 6000 tonnes of XCarb® recycled and renewably produced sections. Through combined efforts between ArcelorMittal Europe – Long Products and the ArcelorMittal International Singapore office, Continental Steel are convinced they will gain a competitive advantage by being among the first distributors in Asia to promote and sell low CO2 emissions steel.

In Singapore, the demand for green steel in the construction industry is growing. Buildings account for over 20% of carbon emissions in the country, so reducing CO2 emissions in this sector is a key lever to drive large-scale decarbonisation. In this context, ArcelorMittal Europe – Long Products and the ArcelorMittal International Singapore office's combined efforts in offering XCarb® recycled and renewably produced sections convinced one of our best stockist customers in Singapore to become the first in export sales to join the action.

Value creation by enhancing engineering and preserving the environment

"We are delighted to be the first in Asia to offer ArcelorMittal’s recycled and renewably produced steel that has been certified,” says Melvin Soh, Executive Director of Continental Steel Pte Ltd. “This product is in line with our philosophy of maximising value to our customers, value that is created by enhancing engineering and preserving our environment. Continental Steel is committed to playing a responsible role towards a net-zero future, promoting actions aimed at mitigating climate change. We encourage all stakeholders in Singapore’s built environment to take advantage of this availability and to join us in being responsible for our environment.”

Prateek Aggarwal, Business Area Head – Asia at ArcelorMittal International, said:

“We are very pleased to work with ArcelorMittal Europe – Long Products and Continental Steel on bringing sustainable and innovative steel products to the Singapore market. This order of 6000 tonnes of HISTAR® high strength steel with XCarb® recycled and renewably produced certification is our testimonial to support green building initiatives in Singapore and will further help in the endeavour of low carbon footprints in the construction industry.”

Tony Demarco, Head of Export Sales at ArcelorMittal Europe – Long Products, said:

“We are very pleased that our XCarb® recycled and renewably produced steel is now entering the Asian market thanks to Continental Steel and the ArcelorMittal International Singapore office. They are our first export client to benefit from HISTAR® high strength steel together with the low carbon emissions that our new XCarb® recycled and renewably produced range now allows. It is a great satisfaction for us to support Continental Steel’s sustainability vision as well as enabling their own customers to decarbonise their supply chain.”

Continental Steel and ArcelorMittal: partners for years

Through the ArcelorMittal International Singapore office, Continental Steel in Singapore purchased 6000 tonnes of XCarb® recycled and renewably produced sections in steel grade HISTAR® 460 / S460M for its stock. The sections are column sizes UC356x406 and HD400 ranging from 237 kg/m to 900 kg/m, which will be produced in the Differdange plant in Luxembourg.

Continental Steel will offer the first and largest stock of XCarb® recycled and renewably produced sections in South East Asia from their warehouse in Singapore. They are convinced their move will help to strengthen their market position in supplying sections to construction projects in the region.

Continental Steel and ArcelorMittal Europe – Long Products (through the ArcelorMittal International Singapore office) have been partnering for years already. As an example, ArcelorMittal HISTAR® beams are at the heart of the Jewel Changi Airport in Singapore. Today, thanks to their loyalty and trust, Continental Steel are helping to spearhead the South East Asian market with XCarb® recycled and renewably produced, which fits perfectly with the HISTAR® range. When lean design using high strength HISTAR® 460 sections is combined with XCarb® recycled and renewably produced steel, designers can drive low carbon solutions. Pairing a low embodied carbon manufacturing process with high strength steel can deliver very high carbon reductions.

ArcelorMittal's next joint projects with Continental Steel will be to deliver steel sections to upcoming major infrastructure developments like underground stations, expressways, and aviation hub expansion projects in Singapore. Pioneering with green steel and ArcelorMittal's XCarb® recycled and renewably produced sections is a step for Continental Steel towards gaining a competitive advantage.

About Continental Steel

Continental Steel is one of the largest premier steel suppliers in South East Asia. Privately held and Singapore-based, they deliver market-leading engineering, structural steel, and service solutions for all urban built environment needs. Continental Steel has had many different roles in its 40-year history delivering innovation to its customers, addressing present and future requirements. Continental Steel puts sustainability at the core of their business strategy and takes pride in working towards lowering the world’s carbon footprint and creating a better future for generations to come.

More information: http://www.consteel.com.sg

Text:

ArcelorMittal Europe Communications

Images:

ArcelorMittal & Continental Steel

Related link(s)

Commercial contacts

Contacts

-

ArcelorMittal Commercial Sections - Austria GmbH

Sales Austria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Netherlands B.V

Sales Belgium & The Netherlands

ArcelorMittal Commercial Sections -

ArcelorMittal Zenica

Sales Bosnia & Herzegovina

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Bulgaria

Sales Bulgaria

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Czech

Sales Czech Republic

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Denmark ApS

Sales Denmark

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Finland OY

Sales Finland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections France S.A.S

Sales France

ArcelorMittal Commercial Sections -

ArcelorMittal Träger und Spundwand GmbH

Sales Germany & Switzerland

ArcelorMittal Commercial Sections -

Arcelor Mittal Commercial FCSE Greece Ltd.

Sales Greece & Cyprus

ArcelorMittal Commercial Sections -

Gudmundur Arason EHF

Sales Iceland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Sections Italia Srl

Sales Italy

ArcelorMittal Commercial Sections -

Steligence Fabrication Center - ArcelorMittal Commercial Sections SA.

Beam Finishing

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Norway A/S

Sales Norway

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Polska

Sales Poland

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Romania S.R.L.

Sales Romania

ArcelorMittal Commercial Sections -

ArcelorMittal Comercial Perfiles España S.L

Sales Spain

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Sweden A.B.

Sales Sweden

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long Çelik Deş Ticaret A.Ş.

Sales Turkey

ArcelorMittal Commercial Sections -

ArcelorMittal Commercial Long UK Ltd

Sales UK

ArcelorMittal Commercial Sections -

ArcelorMittal International Azerbaijan

Sales Azerbaijan

ArcelorMittal International -

ArcelorMittal International Africa

Sales Africa

ArcelorMittal International -

ArcelorMittal International Brazil

Sales Brazil

ArcelorMittal International -

ArcelorMittal International Chile

Sales Chile

ArcelorMittal International -

ArcelorMittal International Beijing

Sales China

ArcelorMittal International -

ArcelorMittal International Shanghai

Sales China

ArcelorMittal International -

ArcelorMittal International Urumqui

Sales China

ArcelorMittal International -

ArcelorMittal International Colombia

Sales Colombia

ArcelorMittal International -

ArcelorMittal International Ecuador

Sales Ecuador

ArcelorMittal International -

ArcelorMittal International Egypt

Sales Egypt

ArcelorMittal International -

ArcelorMittal International Mumbai

Sales India

ArcelorMittal International -

ArcelorMittal International Korea

Sales Korea

ArcelorMittal International -

ArcelorMittal International Mexico

Sales Mexico

ArcelorMittal International -

ArcelorMital Projects Nigeria

Sales Nigeria

ArcelorMittal International -

ArcelorMittal International Peru

Sales Peru

ArcelorMittal International -

ArcelorMittal International Moscow

Sales Russia

ArcelorMittal International -

ArcelorMittal International Senegal

Sales Senegal

ArcelorMittal International -

ArcelorMittal International Singapore

Sales Singapore

ArcelorMittal International -

ArcelorMittal International South Africa

Sales South Africa

ArcelorMittal International -

ArcelorMittal International Taiwan

Sales Taiwan

ArcelorMittal International -

ArcelorMittal International Celik Dis Ticaret A.S.

Sales Turkey

ArcelorMittal International -

ArcelorMittal International FZE

Sales United Arab Emirates

ArcelorMittal International -

ArcelorMittal International North America

Robert Caroti - Sales USA

ArcelorMittal International -

ArcelorMittal International Ukraine

Sales Ukraine

ArcelorMittal International -

ArcelorMittal International Venezuela

Sales Venezuela

ArcelorMittal International -

ArcelorMittal International Vietnam

Sales Vietnam

ArcelorMittal International -

ArcelorMittal International Luxembourg

Sales International

ArcelorMittal International -

ArcelorMittal International North America

Dhiren Patel - Sales Canada

ArcelorMittal International

Technical contacts

Contacts

-

Steligence®

Technical Advisory

ArcelorMittal Commercial Sections