The Angelhy research project

Funded by the European Commission and in partnership with ArcelorMittal Belval & Differdange SA (AMBD), the objectives of the Angelhy research project (conducted over 42 months between 2017 and 2020) included the development of design rules that exploit the carrying potential of angle sections, the improvement of existing rules for built-up sections, and the incorporation of innovative types of built-up sections composed of two angles with unequal sections.

The scope of the project involved:

- market analysis of transmission towers (installation of new lines and reinforcement of existing lines)

- case studies on telecommunication and transmission towers

- testing on lattice towers with high strength steel in S460

- testing of hybrid members

- design rules developed and followed by full scale tests on complete towers

- guidance created on analysis models and design for complete towers (e.g. buckling resistance of back-to-back connected angle section members and classification system for equal leg angle cross sections)

- design recommendations for Eurocode 3

Watch the recorded presentation of the Angelhy project findings:

Angelhy research project: Innovative developments and solutions for steel lattice towers

Steel lattice towers are built around the globe with many serving as telecommunication or power transmission towers. They are commonly composed of equal leg angle sections, ranging from light to heavy sections with leg lengths up to 300 mm.

To meet the increasing demands of renewable energies, which are often decentralised in their production with new lines required to transport energy from the production location to the end users, the European Network of Transmission System Operators for Electricity (ENTSO-E) expect 18 000 kilometres of new transmission lines to be constructed in Europe by 2035. Additionally, telecommunication advances, such as 5G, require the construction of new towers and the reinforcement of existing towers.

The Angelhy research project was conducted in order to optimise the design and reinforcement of these steel lattice towers. The results of the project offer a critical view of the current design standards for steel lattice towers, the presentation of new and economic design rules for single angle and built-up members, the strengthening of lattice tower members with carbon fibre reinforced polymer (CFRP) strips, and a performance-based approach for estimating the reliability of steel lattice towers.

Published: 18 July 2023

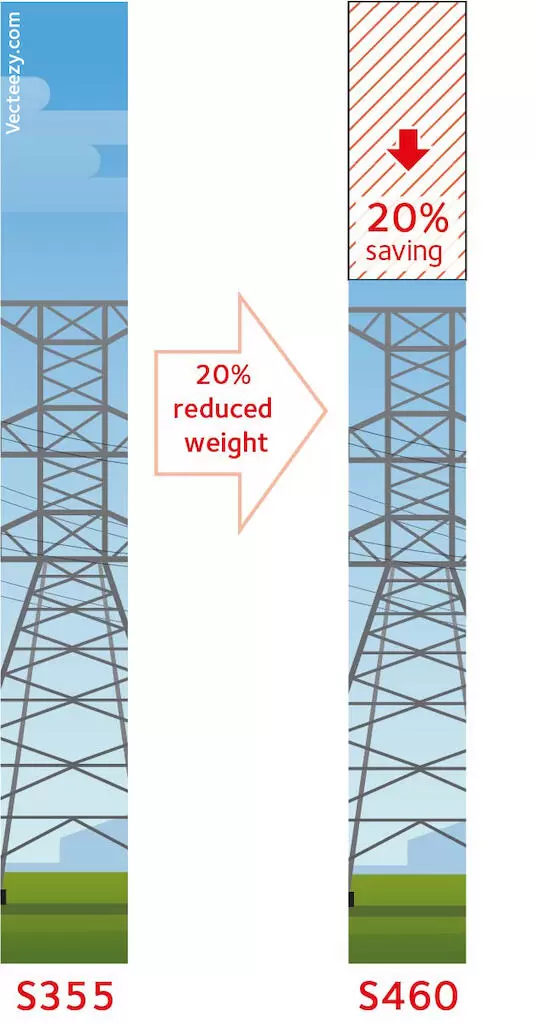

Key finding: Weight reduction using S460

Often built in difficult terrain with limited access for heavy vehicles, steel lattice towers made of fully recyclable hot rolled angle profiles are a typical solution for transmission and telecommunication towers.

A case study was designed to identify a common typology for transmission towers in Europe followed by the design of single towers (as the focus was on angle profiles and structural behaviour) according to EN 50341-1:2021, with comparison to EN 1993-1-1, EN 1993-3-1, and nonlinear design methods. This case study was used as the basis for further research within the Angelhy project.

Design assumptions included steel grade S355 J2 according to EN 10025-2:2004. It is worth noting that EN 50241 (and the German National Annex – as the design was based in Germany) does not include high strength steel grades. EN 50241 and the German National Annex only include steel grades S235 and S355 in J0 and J2.

Automatic optimisation using TOWER v15 software was conducted to find the lightest structure with the highest utilisation degree. It was found that the weight of the structure can be reduced by using S460 for leg profiles and horizontal members in cross-arms. For example, the designed dead-end tower in S355 had a total weight of 66 tonnes, while the same tower in S460 had a total weight of just 56 tonnes.

The use of high strength steel like S460 in steel lattice towers leads to structural weight and cost reduction, reducing the weight of standardised towers up to 20% compared to normal steel grades (e.g. S355) and resulting in lighter structures which are easier and faster to erect.

Extending the Eurocodes to include the use of S460 would capitalise on what high strength steel can offer.

For further detail, please refer to part 3 of the recorded presentation of the research project.

Key finding: New rules for single and built-up angle members

The research project encompassed design rules for single angle members (equal leg angles) and built-up members (back-to-back connected members and star battened members), such as those found in EN 1993-1-1 and EN 1993-3-1 (with references to EN 1993-1-5 and EN 50341). As the rules and formulae used in most codes have been developed mainly for I or H sections, there are some inconsistencies and missing rules within these normative documents. A new failure mode was observed (segment instability) requiring the development of a specific design formula. Therefore, one major objective of the project was to develop design rules for the classification and resistance of angle cross-sections and for the resistance and stability of members with an angle profile.

Notable results include:

Single angle members

- A pure torsional instability mode can be achieved only if the member is loaded at the shear centre, which is not the case in pylons.

- A tendency for the angles to buckle along the weak axis even if the instability mode is a flexural tortional one was observed, meaning that calculations need to be simplified.

- A buckling curve a with a doubling plateau should be used for lateral tortional buckling instead of curve d as the current code proposes.

- The segment instability failure mode, defined as “an instability mode associated with the buckling of more than one member forming a segment,” requires the development of a specific design formula. A simplified model disregards the rotational rigidity of the main leg, so a final model was developed to factor this in.

Built-up members

- The resistance of built-up members was studied. While several design methods exist, there is inconsistency between different design approaches for closely spaced built-up members. Clearer design methods were developed in the research project for major axis buckling of back-to-back connected members under compression and for star battened members under combined compression and bending.

For further detail, please refer to part 4 of the recorded presentation of the research project.

Presentation slides

Steel grades

Recorded presentation speakers:

Prof. L. Vayas, NTUA, Athens

M. Tibolt, ArcelorMittal Global R&D, Luxembourg

M.Z. Bezas, Université de Liège, Liège

S. Reygner, Sika France, Le Bourget

Prof. D. Vamvatsikos, NTUA, Athens

M. Friehe, RWTH Aachen

F. Kemper, RWTH Aachen

Text:

ArcelorMittal Commercial Sections

Constructalia

Angelhy

Images:

ArcelorMittal

Angelhy

Video:

Steligence